Published by : Junaid Rashid Student at central university of kashmir, department of physics

• Stress is defined as the deforming force per unit area. Numerically it is given as; Stress= Force/Area. It’s S.I unit is newton/metre squared.

• Strain is defined as the ratio of change in the configuration to the original configuration of the body.

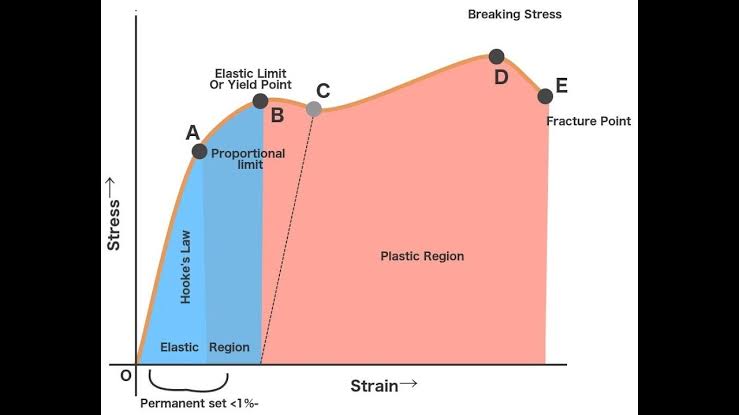

• At point ‘o’ both stress and strain are equal to zero.

• When stress is applied on a body, strain is produced in it. If we remove stress, strain also disappears and increase in stress causes increase in strain in the body.

• The maximum value of stress upto which strain is proportional to stress is called as proportional limit. In this region, body is perfectly elastic i.e, Hooke’s law is valid.

• Point ‘A’ is called as proportional limit and region ‘oA’ is known as proportional region.

• ‘AB’ region is curved which means that stress is no more proportional to strain. However if the deforming load is removed at any point upto ‘B’, the curve retraces its original path along ‘BAo’ which implies that wire attains it’s original length. Thus upto point ‘B’, forces are conservative in the sense that when material returns to it’s original configuration, the work done in producing the deformation is completely recovered.

• Region ‘oB’ is called as elastic region and point ‘B’ is called elastic limit or upper yield point. Stress corresponding to point ‘B’ is known as yield strength.

• Upper yield point (B) represents the maximum stress upto which material is deformed elastically i.e, though material undergoes deformation but once the deforming force is removed, body regains it’s original configuration.

• Beyond upper yield point ‘B’, strain increases more rapidly than stress and even if load is completely removed at any point between ‘B’ and ‘C’, body doesn’t retrace it’s original path but retraces another path represented by a dotted line in the graph and wire is said to be in permanent set.

• The fact that stress-strain curve is not retraced on reversing the strain is called as elastic hysteresis.

• Point ‘C’ is called as lower yield point representing the stress at which deformation is completely plastic.

• Point ‘D’ represents the breaking stress for the given material. Breaking stress is the maximum stress which a material can withstand before it finally breaks. It is important to mention here that breaking stress of a given material is independent of it’s dimensions like length and area but depends on the nature of the material.

• Breaking stress is also called the tensile strength or ultimate strength of the material.

• After point ‘C’, material experiences high rate of plastic deformation and once the material yields, it begins to strain harden which increase its strength. This increase in strength is the result of strain hardening and is observed between yield point (C) and ultimate point (D). The ratio of ultimate strength to yield strength is called as strain hardening ratio and is used to measure the degree of strain hardening in the material.

• Finally with further increase in the deforming load, wire breaks at point ‘E’ called as breaking point or fracture point.

• The region between ‘B’ and ‘D’ is known as plastic region and the deformation as plastic deformation. Plastic deformation is an irreversible deformation of a material.

• It is quite important to note that stress is not a vector quantity but it is a tensor. The tensor nature of stress can be explained as follows:

• The stress acting on any surface of a body can be resolved into its three mutually orthogonal components. One component is along the normal to the surface representing normal stress while remaining two components are tangential to the surface representing shear or tangential stress. Normal stress tends to change the volume and is resisted by the bulk modulus of the material while shear stress tends to deform the material without changing it’s volume and is resisted by body’s shear modulus.

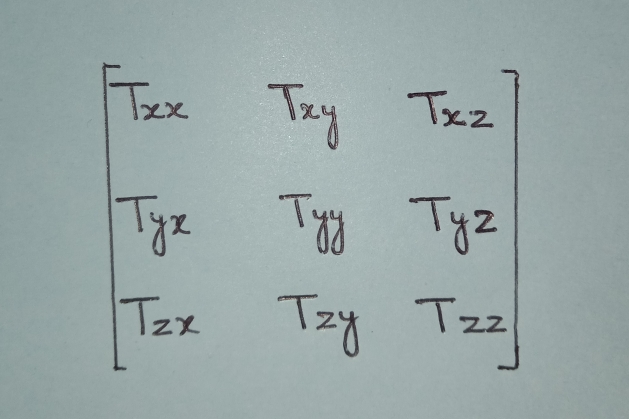

• Consider an internal point ‘P’. The stress state at this point can be represented by an infinitesimal cube with three stress components on each of it’s six sides- one normal and two tangential. Since each point in the body is under static equilibrium i.e, net force acting on each point is zero hence only nine stress components, three from each plane are required to describe the stress state at any arbitrary point ‘P’. In determinant form the stress state at point ‘P’ can be represented by a matrix of three rows and three columns as shown below.

• As a consequence of static equilibrium, the shear stresses along the diagonal are identical i.e, Txy= Tyx ,Tyz=Tzy , Tzx=Txz

• This grouping of nine stress components in a matrix is called as stress tensor or stress matrix.

• The subscript notations used for nine stress components have the following meanings: first subscript represents the direction of surface normal upon which stress is acting while the second subscript represents the direction of stress component.

• From the above discussion, we conclude that stress is a second order tensor as it is a quantity associated with two directions.That is why each component is having two subscripts. On the other hand, vector quantity is a first order tensor as it is associated with only one direction due to which each component of a vector quantity has only one subscript. Accordingly, a scalar quantity is a zero order tensor as it is direction independent and gives only magnitude.

THE END..